Top CNC Cabinet Software Features: Best Cnc Cabinet Software

Ah, my friend, the heart of cabinet making lies not just in the skillful hands, but in the precision of the tools and the intelligence of the software guiding them. Choosing the right CNC cabinet software is akin to selecting the finest wood for a masterpiece – the foundation upon which beauty and efficiency are built. Let us delve into the core features that distinguish the best from the rest.

Comparison of Popular CNC Cabinet Software Packages

Selecting the perfect software can feel overwhelming, but a clear comparison helps. Below, we examine three leading packages, focusing on their core strengths, pricing, and user feedback. Remember, the “best” software depends heavily on your specific needs and budget.

| Software Name | Key Features | Pricing Model | User Reviews Summary |

|---|---|---|---|

| (Software A – replace with actual software name) | (List key features: e.g., 3D modeling, nesting optimization, library of cabinet components, import/export capabilities, etc.) | (e.g., Subscription, Perpetual License, etc. Include pricing tiers if applicable) | (Summarize user reviews: e.g., “Generally positive, praised for ease of use and powerful features, some complaints about customer support.”) |

| (Software B – replace with actual software name) | (List key features: e.g., advanced rendering capabilities, integrated CAM module, extensive material database, etc.) | (e.g., Subscription, Perpetual License, etc. Include pricing tiers if applicable) | (Summarize user reviews: e.g., “Highly rated for its rendering capabilities and robust features, but some users find the interface less intuitive.”) |

| (Software C – replace with actual software name) | (List key features: e.g., strong nesting algorithms, focus on efficiency, user-friendly interface, etc.) | (e.g., Subscription, Perpetual License, etc. Include pricing tiers if applicable) | (Summarize user reviews: e.g., “Known for its efficiency and ease of use, particularly appreciated by smaller shops, limited advanced features.”) |

Cloud-Based vs. Locally Installed Software

The choice between cloud and local installation is crucial. Each offers distinct advantages and disadvantages that resonate deeply with the craftsman’s soul.

Best cnc cabinet software – Consider these points carefully:

- Cloud-Based Advantages: Accessibility from anywhere with an internet connection, automatic updates, often lower upfront costs, collaborative features.

- Cloud-Based Disadvantages: Reliance on internet connectivity, potential security concerns, subscription fees, possible limitations on offline use.

- Locally Installed Advantages: No internet dependency, greater control over data security, potentially faster processing speeds for complex designs, ownership of the software.

- Locally Installed Disadvantages: Higher upfront costs, manual updates, requires dedicated computer resources, limited accessibility.

Importance of Design Capabilities

The ability to visualize your creation before a single cut is made is paramount. 3D modeling and rendering capabilities are no mere luxuries; they are the architects of efficiency and precision. Imagine, my friend, the ability to rotate, zoom, and examine every detail of your design, ensuring perfect fit and flawless execution. This reduces costly errors, saves precious time, and allows for seamless client communication. For instance, a designer can easily show a client different door styles in 3D, complete with realistic wood grain textures, far exceeding the limitations of 2D drawings.

Role of Nesting Optimization

Nesting optimization is the heart of efficient material usage. It’s the art of arranging multiple cabinet parts within a single sheet of material to minimize waste. Imagine a jigsaw puzzle, but instead of whimsical shapes, you have precise cabinet components. The software cleverly arranges these pieces, minimizing the material used and reducing costs. For example, a simple nesting algorithm might arrange rectangular cabinet doors in a straightforward manner, while an advanced algorithm might consider irregular shapes and optimize for minimizing leftover scraps. This seemingly small detail translates to significant savings in the long run, a testament to the software’s power.

Software Selection Criteria for Cabinet Makers

Choosing the right CNC cabinet software is akin to selecting the perfect chisel for a master craftsman – the wrong tool can lead to frustration and flawed creations, while the right one empowers precision and artistry. The decision extends far beyond mere price; it’s about aligning software capabilities with your workshop’s specific needs and your long-term vision. This careful selection ensures efficiency, accuracy, and ultimately, the satisfaction of delivering exquisite cabinetry.

Three crucial factors, beyond price, must be carefully considered when selecting CNC cabinet software. These factors are interconnected and influence each other, forming a holistic evaluation process. Ignoring any one of them risks compromising the overall effectiveness and return on investment.

Crucial Factors in CNC Cabinet Software Selection, Best cnc cabinet software

Cabinet makers should prioritize these three key factors: Software compatibility with existing machinery, the software’s design capabilities and features directly relevant to their typical projects, and the software’s ease of use and learning curve.

- Compatibility with Existing Machinery: This involves verifying that the software seamlessly integrates with your existing CNC router, ensuring smooth data transfer and precise control over the machine’s movements. Incompatibility can lead to costly downtime and frustrating errors. For example, if you have a specific brand of CNC router known for its unique G-code dialect, the software must support that dialect flawlessly.

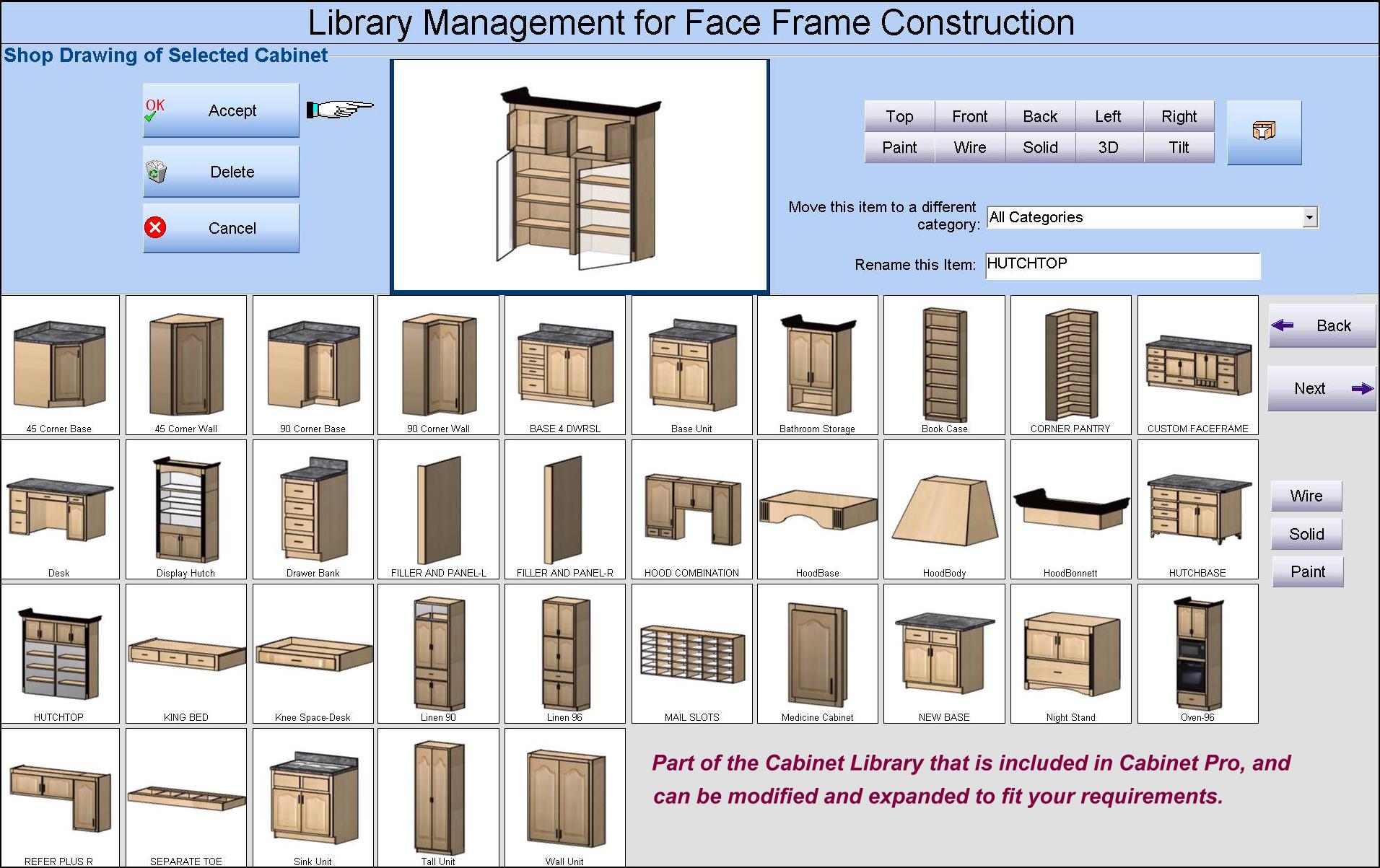

- Design Capabilities and Features: The software should possess the specific design tools and features necessary for your typical projects. Does it offer robust 3D modeling? Does it provide accurate nesting capabilities to minimize material waste? Does it support custom design elements that you frequently incorporate into your work? A lack of these features will severely hinder your workflow and limit your creative potential. For instance, if you specialize in intricate inlay work, the software needs advanced features to handle those details precisely.

- Ease of Use and Learning Curve: The software should be intuitive and user-friendly. A steep learning curve can significantly impact productivity, especially in the initial stages of implementation. Look for software with clear documentation, helpful tutorials, and responsive customer support. The time and effort spent mastering the software should be proportionate to its benefits. Consider software with a user-friendly interface and well-structured tutorials, especially if your team lacks extensive CAD/CAM experience.

Decision-Making Flowchart for CNC Cabinet Software Selection

This flowchart guides cabinet makers through a structured decision-making process. Each step is crucial for making an informed choice that aligns with both your budget and your long-term business goals.

Imagine a flowchart, starting with a diamond shape representing “Define your needs and budget”. From there, two paths branch out: “Needs exceed budget” leading to a box suggesting “Explore budget-friendly options, prioritize essential features”, and “Budget accommodates needs” leading to a box labeled “Assess software compatibility, design capabilities, and ease of use”. This then branches to boxes for each of these assessments. Each assessment leads to a final decision point “Select software”. If the assessment is negative for any of the three factors, the process loops back to explore alternative software options.

Evaluating Ease of Use and Learning Curve

Practical evaluation of software ease of use should involve hands-on testing, preferably with a trial version. Focus on the software’s interface intuitiveness, the clarity of its documentation, and the availability of tutorials or online support. Consider how easily you can perform common tasks, such as creating basic cabinet designs, generating toolpaths, and simulating the CNC machining process. A steep learning curve might manifest as frequent errors, difficulty in navigating menus, and an overall sense of frustration. A user-friendly software should facilitate a smooth and efficient workflow, minimizing training time and maximizing productivity.

Hypothetical Scenario: Software Selection for a Cabinet Maker

Imagine a cabinet maker specializing in high-end custom kitchens. They need software capable of handling complex designs, intricate details, and efficient material nesting. Their budget allows for a mid-range investment. They would first define their needs (complex 3D modeling, advanced nesting, support for specialized joinery), and then compare several software options. They would test trial versions, focusing on ease of use for their team. They would check compatibility with their existing CNC machine and assess whether the design capabilities match their project requirements. Based on this rigorous evaluation, they would select the software that best balances functionality, usability, and cost-effectiveness.